Product Overview

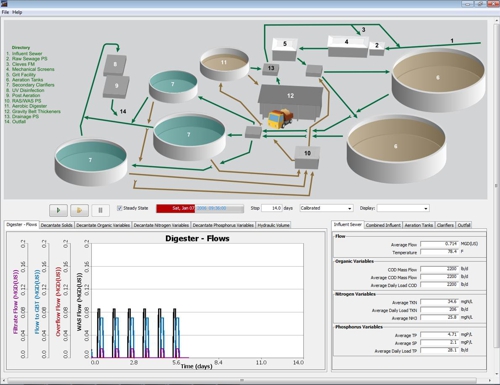

Customized Operator Interfaces for Advanced Training and Plant AnalysisSimuWorks™ is an industry first – a flight-simulator for water and wastewater treatment plants. Leveraging the proven technology of Hydromantis’ GPS-X™, the industry’s most advanced mathematical modelling and simulation software, SimuWorks™ takes training and plant analysis opportunities to new heights. SimuWorks™ represents an evolution in the use of water and wastewater treatment simulation and modelling technology, extending its use beyond the engineering offices. Utilizing customized operator interfaces, SimuWorks™ presents views and functionality familiar to operators and administrators alike in a platform that accurately simulates the behavior of a specific plant.

These site specific calibrated models, deployed within customized operator interfaces or dashboards, offer:

SimuWorks™ can be deployed as a complete life-size replica of a specific control room, set-up as a mobile control room for regional training with a library of various plant models, used in more traditional multi-station classroom environments or loaded on individual workstations. Advanced Operator Training and DevelopmentSimuWorks™ is a state of the art operator training and development platform that allows instructors to train and evaluate new or existing operators in a controlled and safe environment. The training can offer actual SCADA or customized look interfaces tied to the plant models that closely simulate actual plant behaviour. The training offers exposure to many simple or highly complex scenarios within a realistic environment but with no risk to actual plant performance. Plant and Process OptimizationSimuWorks™ offers a platform for fast and efficient testing and validation of any number of plant optimization or upgrade possibilities without putting the plant at risk. Operators, engineers, management or any other user type can evaluate new technologies, test new operational control strategies, run “what-if” scenarios (capacity, flow rates, chemical dosing, energy usage, etc.) and more. The implementation of SimuWorks™ can promote a better understanding of plant control at all levels within an organization. Project Management and Risk AnalysisSimuWorks™ becomes an important part of the planning process for projects. By simulating various scenarios around downtime for plant maintenance or modifications, potential risks can be identified and optimum project planning achieved. |